There are pivotal moments in the life cycle of every business when transformation is essential. Gordon Brothers provides the global expertise and reliable liquidity organizations need to make the most of these moments—transforming your business and your balance sheet.

50+

countries in which we operate

10M

historical sale data points

$1T+

of assets appraised

$150B

of assets sold

$2.5B

of capital deployed

See all we do.

Expertise, ready to deploy.

With 30 offices and over 700 experienced professionals worldwide, we’re ready where and when you need us.

Our Team

Creativity to make the most of the moment.

Gordon Brothers rapidly customizes solutions to help companies maximize assets, minimize liabilities and extend the life cycle—with guaranteed outcomes.

Our Services

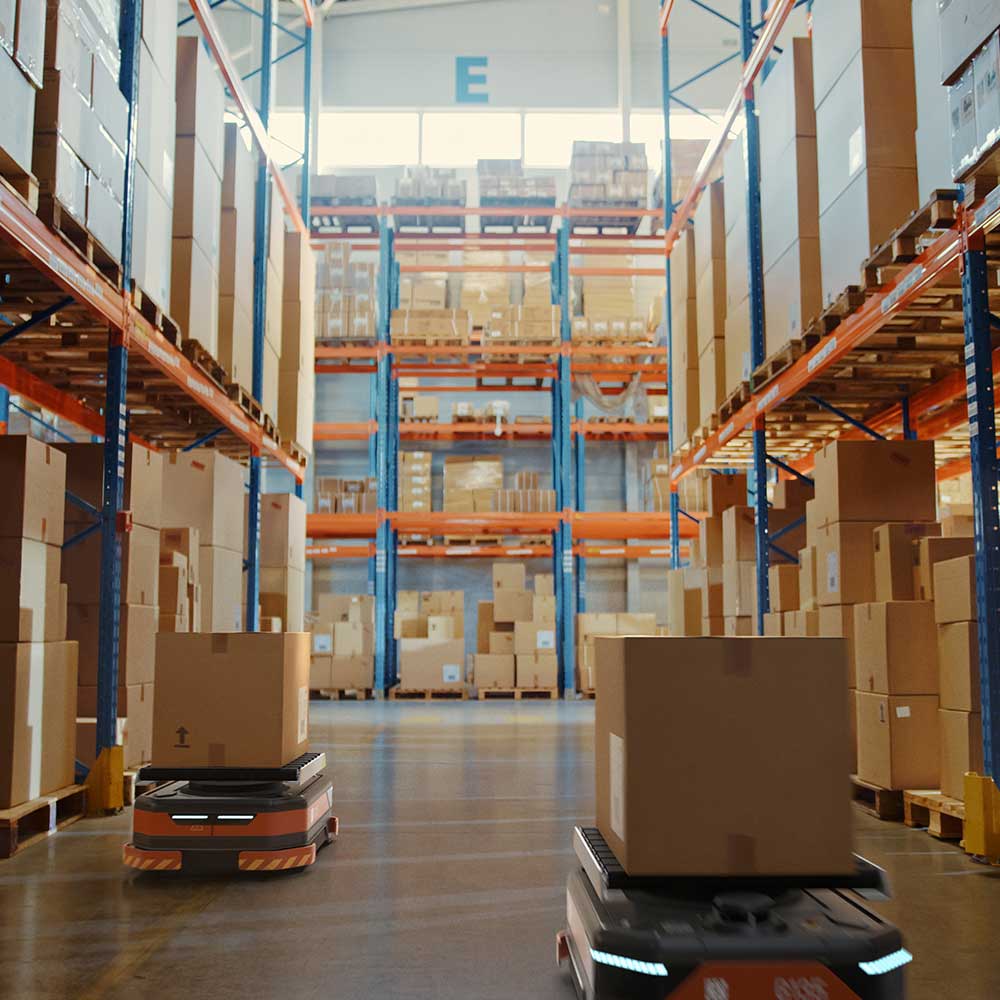

Industrial-strength

perspective.

Our clients benefit from more than a century of experience that spans industries and market sectors across the globe.

Industries we serveYour industries. Our insights.

Insights, delivered right

to your inbox.

Sign up to receive insights, event information

and company news.